Lafarge Precast proudly secured the design, supply, and installation contract for the City of Prince Albert’s water reservoir expansion, a key infrastructure project to bolster water storage capacity. A new 15-million-litre precast tank doubled the city’s water storage capability to provide up to 4 days of emergency supply.

This project is a testament to Lafarge Precast’s collaborative strength and innovative engineering. By combining Lafarge regional expertise, seeing the Saskatoon team bring their hollowcore proficiency and market knowledge, while the Edmonton team contributed their vast experience in large-volume precast tank design and assembly. Together, developing an innovative precast solution:

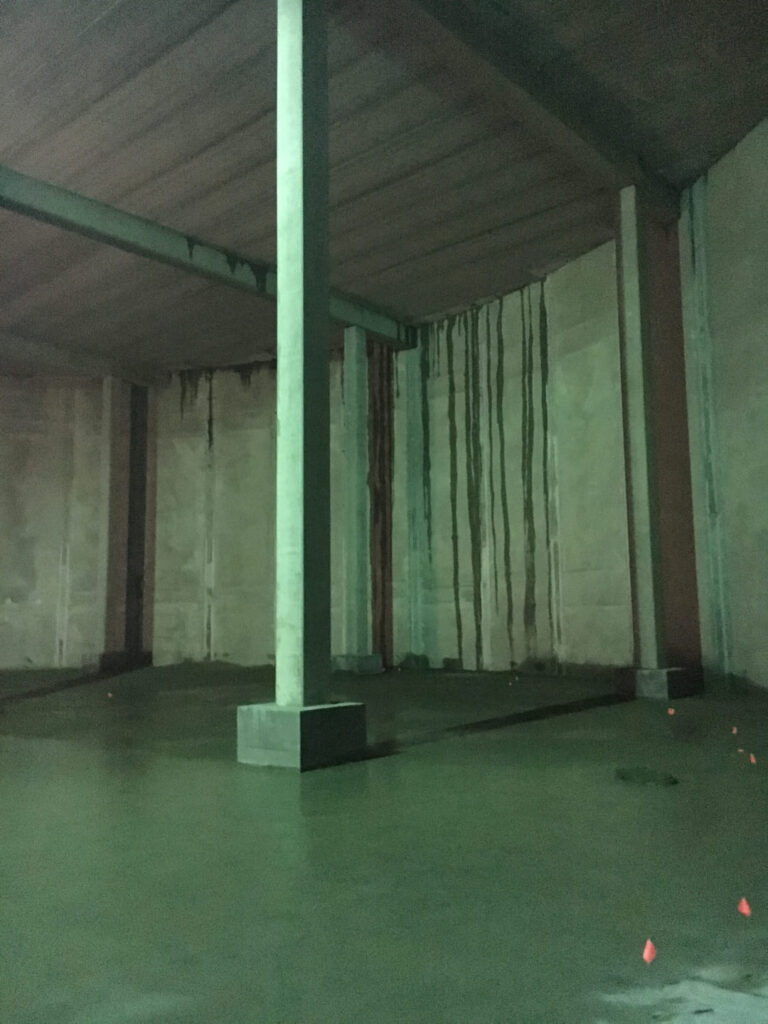

- Curved precast panels formed the tank’s large-diameter cylindrical walls.

- Hollowcore planks were used to construct the roof structure.

- Circular post-tensioning cables anchored internally, eliminating the need for bulky buttress panels and enhancing the structural integrity by introducing wall compression to mitigate shrinkage and cracking.

- A proven narrow joint system eliminated the need for large cast-in-place joints, optimizing cost and installation efficiency.

The advantages of precast construction were key to the project’s success:

- Shortened Schedules: Precast manufacturing allowed for simultaneous site preparation and off-site component production.

- Reduced On-Site Workforce: Fewer on-site workers enhanced safety and efficiency, especially during winter.

- Weather Resilience: Precast’s adaptability to Canada’s winter conditions ensured uninterrupted progress.

With this expansion, the City of Prince Albert achieves enhanced water security, while Lafarge Precast once again demonstrates its leadership in tackling complex design challenges with innovative and cost-effective solutions.